Selected Case Studies

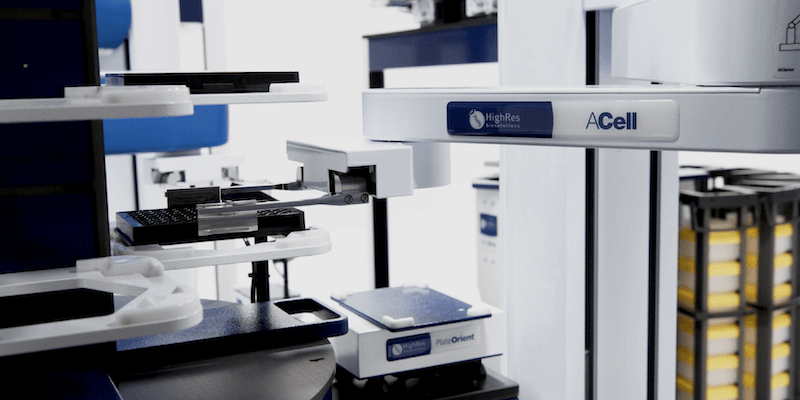

High-Throughput Bioassay Automation

Regeneron (2025) | Role: Automation Engineering Intern

The Challenge: Manual workflow steps were causing variability and bottlenecking critical sample processing.

The Solution: Synchronized 12 robotic devices via Cellario to create a fully automated, consistent bioassay workflow, eliminating manual intervention and increasing throughput 4x.

- Cellario

- Robotics

- Workflow Optimization

Bioprocess Fixture Design (PAT)

Regeneron (2024) | Role: Manufacturing Engineering Intern

The Challenge: Integrating optical sensors for protein measurement required sterile tubing, creating cleaning and sterilization burdens.

The Solution: Engineered a single-use fixture in SolidWorks using GD&T and DFMA principles, integrating optical sensors for inline measurement and contributing to $8M in savings.

- SolidWorks

- GD&T

- GMP

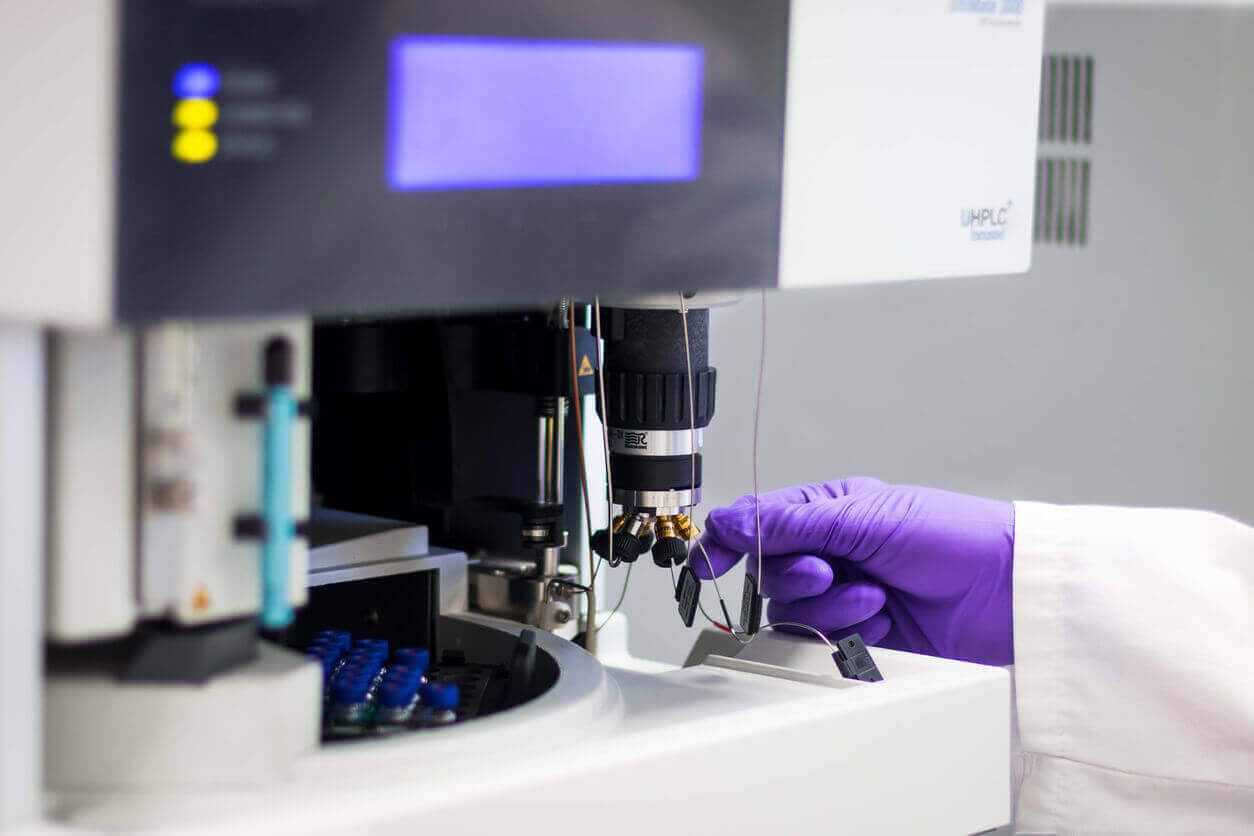

Rapid Antibiotic Susceptibility (SERS)

Ziegler Lab (BU) | Role: Researcher & Data Analyst

The Challenge: Standard testing takes 24-48 hours. Reducing this time is critical to improving survival rates for bacterial infections like sepsis.

The Solution: Developed a Raman Spectroscopy methodology published in Talanta. Used Python analysis to reduce testing time from 48 to under 4 hours.

- Python

- Raman Spectroscopy

- Laboratory

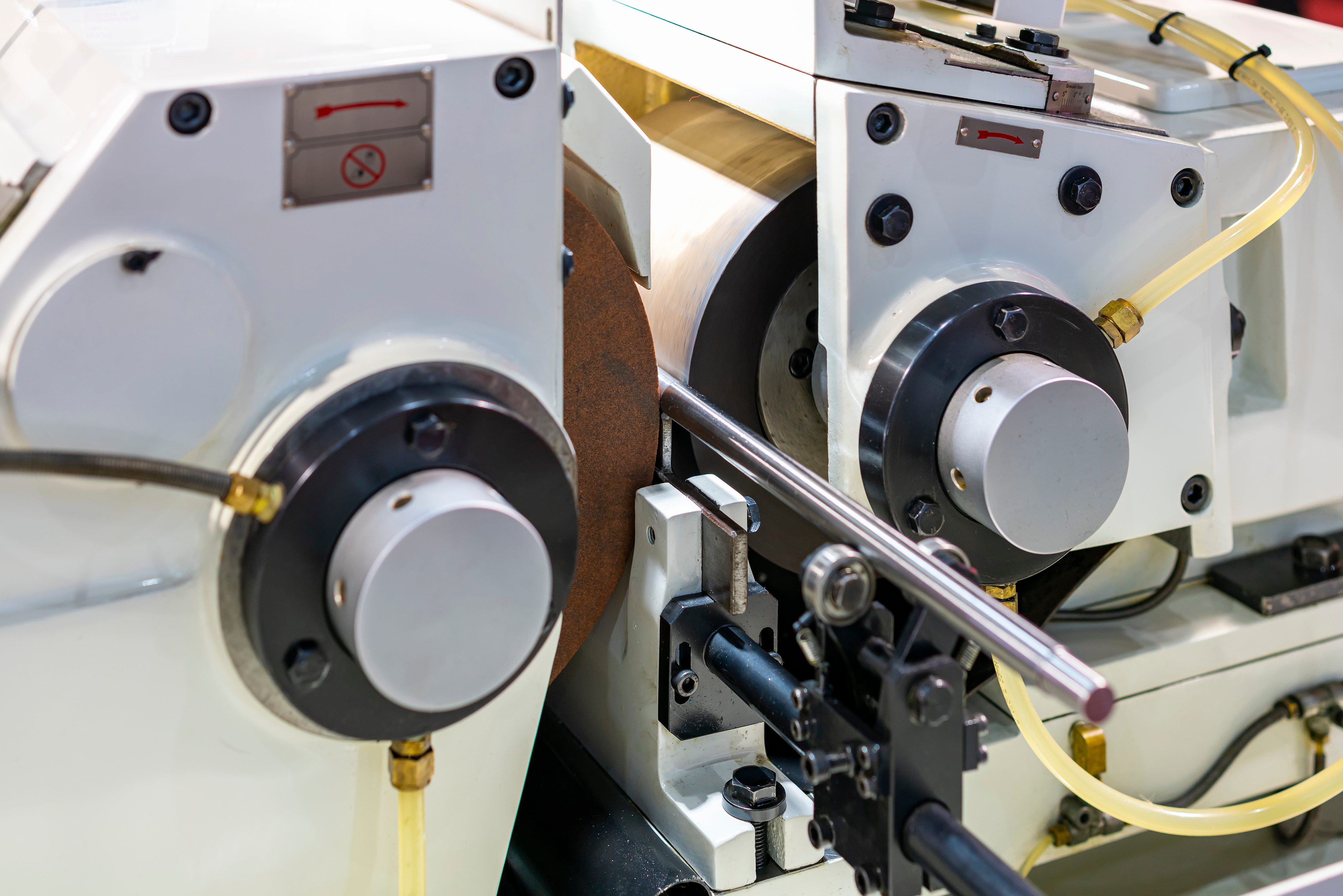

Process Optimization: Centerless Polishing

Client: Vita Needle | Role: Lead Engineer

The Challenge: The client required a standardized finish evaluation and higher throughput for 5-10 ft tubes.

The Solution: Optimized centerless polishing parameters and introduced an automated visual QC subsystem using Python/SSIM inspection logic to increase throughput 6x.

- Python

- Process Improvement

- AI Vision

Robotics: 3-DOF Food Processing Unit

Electromechanical Design Project | Role: Mechanical Lead

The Challenge: Develop a fully autonomous slicing system requiring 0.1 mm positional accuracy.

The Solution: Designed a custom 3-DOF mechanism and developed control logic in Arduino with G-Code for repeatable slicing performance.

- SolidWorks Assembly

- DFMA

- CNC Machining

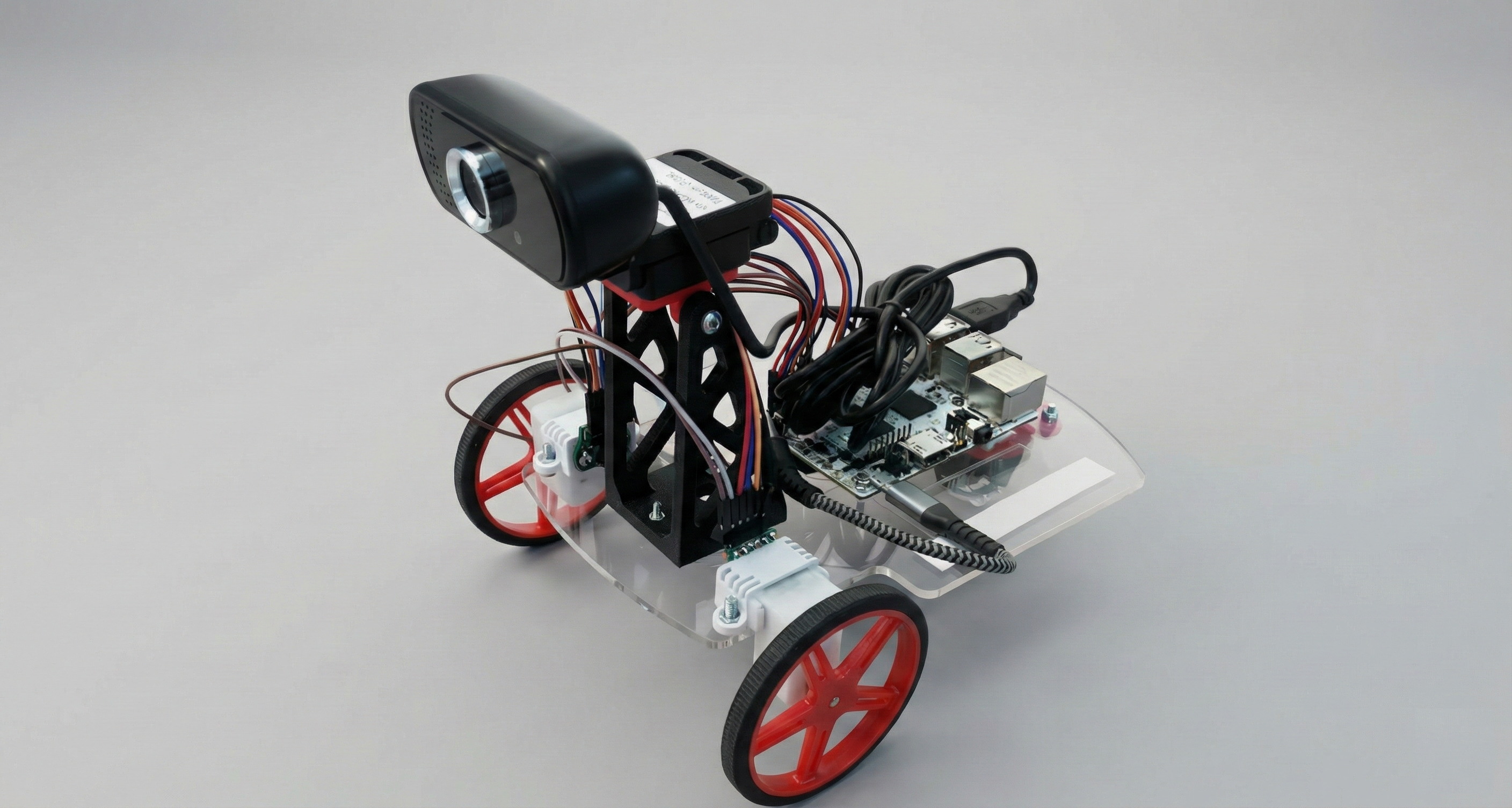

Autonomous Systems: ROS2 Mobile Platform

Independent R&D | Role: Systems Integrator

The Challenge: Create a mobile robot capable of autonomous navigation and obstacle detection.

The Solution: Integrated ultrasonic and IMU sensors for localization and implemented OpenCV routines for line-following within a ROS2 stack.

- ROS2

- OpenCV

- Python

- Motion Control